A

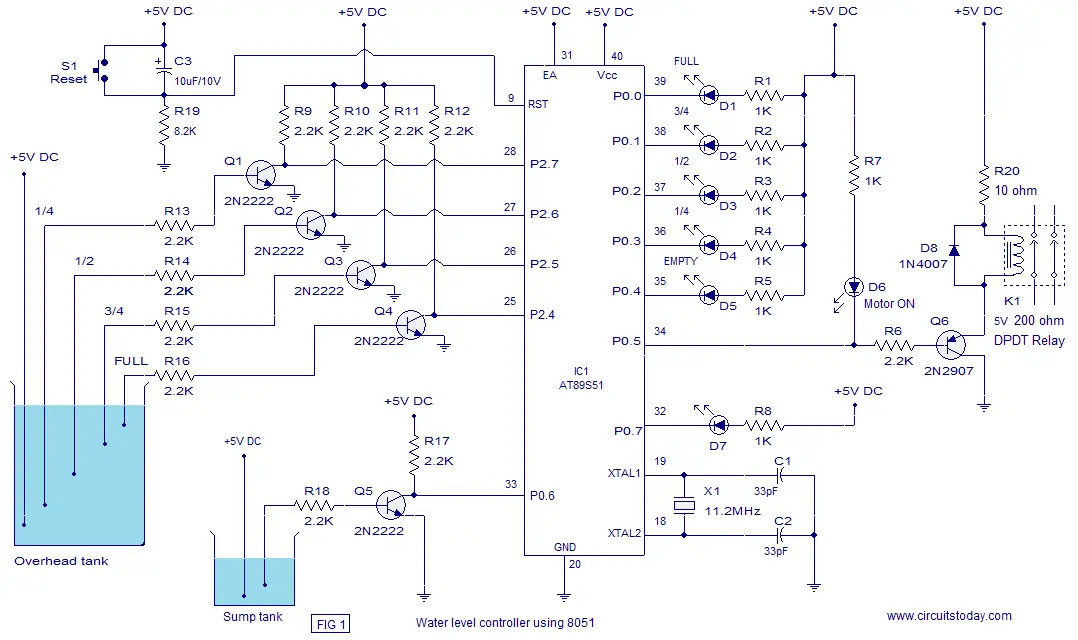

water level controller based using 8051 is shown in this article. A lot

of water level controller projects have been published in this website

but the is the first one based on a microcontroller. This water level

controller monitors the level of the over head tank and automatically

switches on the water pump when ever the level goes below a preset

limit. The level of the over head tank is indicated using 5 leds and the

pump is switched of when the over head tank is filled.

The pump is not allowed to start if the water level

in the sump tank is low and also the pump is switched off when the level

inside the sump tank goes low during a pumping cycle. The circuit

diagram of the water level controller is shown below.

The level sensor probes for the overhead tank are interfaced to the port

2 of the microcontroller through transistors. Have a look at the sensor

probe arrangement for the overhead tank in Fig1. A positive voltage

supply probe goes to the down bottom of the tank. The probes for sensing

1/4, 1/2, 3/4 and FULL levels are placed with equal spacing one by one

above the bottom positive probe. Consider the topmost (full level)

probe, its other end is connected to the base of transistor Q4 through

resistor R16. Whenever water rises to the full level current flows into

the base of transistor Q4 which makes it ON and so its collector voltage

goes low. The collector of Q4 is connected to P2.4 and a low voltage at

P2.4 means the over head tank is not FULL. When water level goes below

the full level probe, the base of Q2 becomes open making it OFF. Now

its collector voltage goes high and high at P2.4 means the tank is not

full. The same applies to other sensor probes (3/4, 1/2, 1/4) and the

microprocessor understands the current level by scanning the port pins

P2.4 ,P2.5, P2.6 and P2.7. All these port pin are high (all sensor

probes are open) means the tank is empty.

Port pin P0.5 is used to control the pump. When ever it is required

start pumping, the controller makes P0.5 low which makes transistor Q6

ON which in turn activates the relay K1 that switches the pump. Also the

LED d6 glows indicating the motor is ON. LED D7 is the low sump

indicator. When the water level in the sump tank goes low, the

controller makes P0.7 low which makes LED D7 to glow. The circuit

diagram of the water level controller is shown in the figure below.

Circuit diagram.

Program.

MOV P2,#11111111B // initiates P2 as sensor input

MOV P0,#11111111B // initiates P2 as the output port

MOV A,#00000000B

MAIN:ACALL SMPCK // checks the level of the sump tank

MOV A,P2 // moves the current status of P2 tp A

CJNE A,#11110000B,LABEL1 // checks whether tank is full

SETB P0.1

SETB P0.2

SETB P0.3

SETB P0.4

CLR P0.0 // glows full level LED

SETB P0.5

LABEL1:MOV A,P2

CJNE A,#11111000B,LABEL2 // checks whether tank is 3/4

SETB P0.0

SETB P0.2

SETB P0.3

SETB P0.4

CLR P0.1 // glows 3/4 level LED

LABEL2:MOV A,P2

CJNE A,#11111100B,LABEL3 // checks whether tank is 1/2

SETB P0.0

SETB P0.1

SETB P0.3

SETB P0.4

CLR P0.2 // glows 1/2 level LED

LABEL3:MOV A,P2

CJNE A,#11111110B,LABEL4 // checks whether tank is 1/4

SETB P0.0

SETB P0.1

SETB P0.2

SETB P0.4

CLR P0.3 // glows 1/4 level LED

JB P0.6,LABEL4

CLR P0.5 // switches motor ON

LABEL4:MOV A,P2

CJNE A,#11111111B,MAIN // checks whether tank is empty

SETB P0.0

SETB P0.1

SETB P0.2

SETB P0.3

CLR P0.4 // glows EMPTY LED

JB P0.6,MAIN // checks whether sump is low

CLR P0.5 // switches motor ON

SJMP MAIN

SMPCK:JB P0.6,LABEL5 // checks whether sump is low

SETB P0.7 // extinguishes the sump low indicator LED

SJMP LABEL6

LABEL5:SETB P0.5 // switches the pump OFF

CLR P0.7 // glows sump low indicator LED

LABEL6:RET

END